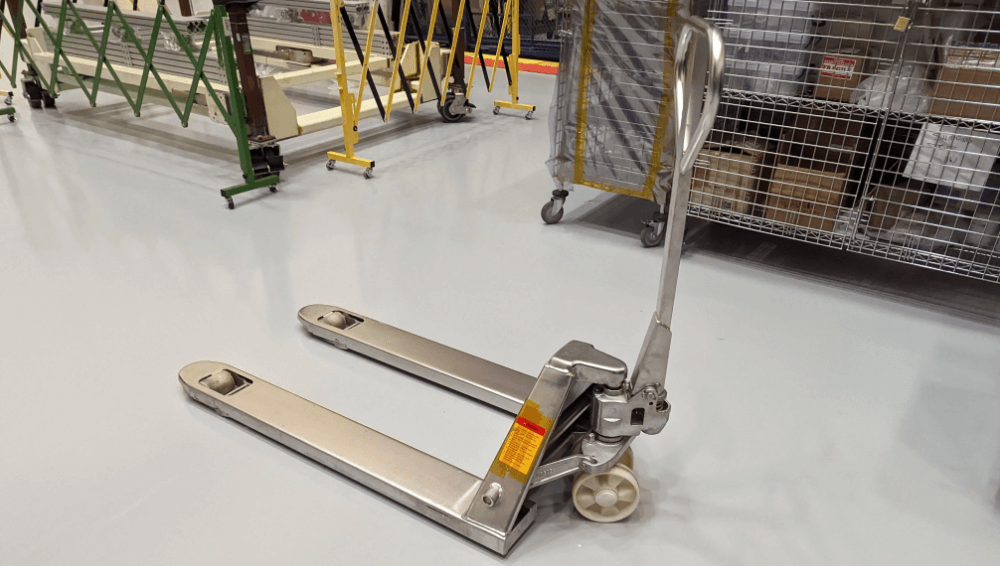

In the realm of material handling and warehouse management, pallet lift trucks have emerged as indispensable tools that streamline operations, boost efficiency, and ensure worker safety. Also referred to as pallet trucks or pallet jacks, these innovative devices have become the backbone of modern logistics and distribution centers, offering a wide range of benefits that facilitate the movement of heavy loads and enhance the overall workflow. This article delves into the realm of pallet lift trucks, exploring their applications, advantages, types, purchasing considerations, and the critical aspect of safety in their usage.

Applications and Advantages of Pallet Lift Trucks

Pallet lift trucks, often known as pallet trucks, play a pivotal role in various industries where the transportation and positioning of heavy loads are a routine task. Warehouses, manufacturing facilities, retail outlets, and distribution centres all benefit immensely from the utilization of pallet lift trucks. These versatile tools are employed to transport palletized goods within confined spaces, offering the flexibility to maneuver through narrow aisles and tight corners that larger equipment might struggle with.

One of the key advantages of pallet lift trucks lies in their ability to enhance worker productivity and reduce physical strain. By eliminating the need for manual lifting and carrying, these devices mitigate the risk of workplace injuries related to lifting heavy objects, such as strained muscles and back injuries. This not only contributes to a safer work environment but also results in reduced downtime due to injuries, ensuring a more consistent workflow.

Exploring the Different Types of Pallet Lift Trucks

Pallet lift trucks come in various types, each tailored to specific tasks and work environments. The three primary categories are manual pallet trucks, electric pallet trucks, and rider pallet trucks.

- Manual Pallet Trucks: These are the most basic and traditional types of pallet trucks. They are operated manually by the operator, who pumps a lever to raise the forks off the ground and moves the load by pushing or pulling the truck. Manual pallet trucks are ideal for lighter loads and smaller spaces where efficiency is crucial.

- Electric Pallet Trucks: Electric pallet trucks are powered by batteries and offer enhanced convenience and efficiency. They eliminate the need for manual pumping, making it easier to lift and move heavier loads. Electric pallet trucks are highly suitable for larger warehouses and distribution centres where frequent and heavy lifting is required.

- Rider Pallet Trucks: Rider pallet trucks, also known as walkie-rider pallet trucks, are designed to accommodate an operator who can ride on the truck while controlling its movements. These trucks are well-suited for applications that involve transporting heavy loads over longer distances. They offer increased operator comfort and speed, contributing to higher productivity levels.

Factors to Consider When Buying Pallet Lift Trucks

Purchasing the right pallet lift truck for a specific work environment requires careful consideration of several factors. These include load capacity, lift height, maneuverability, and maintenance requirements.

- Load Capacity: The load capacity of a pallet lift truck is a critical factor to assess. It’s essential to choose a truck that can comfortably handle the maximum weight of the loads typically encountered in the workplace. Selecting a truck with a higher load capacity than necessary can be wasteful, while choosing one with insufficient capacity can lead to operational inefficiencies and safety risks.

- Lift Height: Lift height refers to how high the forks can be raised. It’s crucial to choose a pallet lift truck with a lift height that matches the storage racks or shelving units in the facility. This ensures that the truck can efficiently load and unload goods at different levels without the risk of damage.

- Maneuverability: Different work environments have varying layouts and space constraints. When selecting a pallet lift truck, consider the maneuverability it offers, especially if the workspace has narrow aisles or tight corners. Smaller manual pallet trucks may be better suited for confined spaces, while electric or rider pallet trucks may be preferable for larger areas.

- Maintenance Requirements: Like any piece of equipment, pallet lift trucks require regular maintenance to ensure their longevity and optimal performance. Consider the ease of maintenance, availability of spare parts, and the manufacturer’s reputation for reliability when making a purchase decision.

Safety Considerations When Using Pallet Lift Trucks

While pallet lift trucks are designed to enhance efficiency and convenience, safety should always remain a top priority. The following safety factors should be diligently observed when operating these devices:

- Operator Training: Proper training is paramount for anyone who will be operating a pallet lift truck. Operators should be familiar with the controls, safety features, and best practices for maneuvering the truck. Training programs should cover topics such as load stability, weight limits, and safe operating speeds.

- Load Distribution: Improper load distribution can lead to instability and potential accidents. Always ensure that the load is evenly distributed on the forks and that it does not exceed the truck’s recommended capacity.

- Clear Pathways: Maintain clear pathways for your pallet lift truck to navigate through the workspace. Remove any obstacles, debris, or clutter that could impede the truck’s movement. This helps prevent collisions and ensures the safety of both operators and pedestrians.

- Speed Control: Pallet lift trucks should be operated at safe and controlled speeds, especially when moving around corners or in areas with limited visibility. Excessive speed can compromise maneuverability and increase the risk of accidents.

- Personal Protective Equipment (PPE): Operators should be equipped with appropriate PPE, including high-visibility vests, steel-toed shoes, and gloves. This protective gear helps reduce the risk of injuries in case of any unforeseen accidents.

- Regular Inspections: Conduct regular inspections of pallet lift trucks to identify any potential issues or malfunctions. Check for worn-out components, such as wheels, forks, and brakes, and address them promptly to prevent accidents.

Conclusion

Pallet lift trucks have revolutionized the way goods are transported and managed in warehouses and distribution centres. These versatile tools not only enhance operational efficiency but also contribute to the safety and well-being of workers by reducing the risk of manual lifting injuries. With various types available to suit different requirements, careful consideration of factors like load capacity, lift height, and maneuverability is crucial when purchasing pallet lift trucks.

By adhering to stringent safety protocols, including proper operator training and routine maintenance, organizations can harness the full potential of pallet lift trucks while ensuring a secure and productive working environment. As the backbone of modern logistics, these machines continue to shape the landscape of material handling, enabling businesses to thrive in the dynamic world of commerce.