If you are designing apparel and decorating them with cool prints, we are sure you must have come across heat transfer vinyl.

Although it might be cool to use HTV on polyester, it needs a little extra care compared to cotton or any other material.

But that does not mean that it is impossible. All that you need is a bit of extra care, and durable and reliable vinyl, like the one in 3M wrap vinyl rolls.

We have all made mistakes while using HTV on polyester but having learned from our mistakes, we have decided to share with you tips you should keep in mind the next time you use heat transfer vinyl on polyester.

Let us begin!

1. Different Types of Polyester

The thing about polyester is that there is no single polyester composition, unlike cotton.

Different types have different compositions, and each needs a separate setting with the HTV.

So, do not be disheartened if you nail the art on one polyester t-shirt but fail with the other.

It is not your fault; maybe you are just dealing with a different polyester material.

To ensure that you do not make any mistakes, always check the t-shirt’s tag to check for the material type and composition before using the HTV on it.

For instance, a 100% polyester sports jersey may require a lower heat setting than a polyester-cotton blend t-shirt.

We once worked with a polyester mesh fabric that required a specific temperature setting, unlike the solid polyester used in another project.

2. Use a Heat Transfer Cover Sheet

You can also use a heat transfer cover to avoid burning the material and saving it from excess heat.

While this cover works well for any material, it is way more important for sensitive materials like polyester and materials you are dealing with for the first time.

Using a heat transfer cover will prevent the material from directly contacting the hot plate.

If you do not have a heat transfer cover, you can also use parchment paper in its place.

In one of our projects, using a heat transfer cover sheet prevented the glossy finish of a polyester bag from getting damaged, unlike an earlier attempt where direct heat caused slight discoloration.

3. Do Not Pre-Wash Your Material

People often ask if they should wash their shirts or outfits before using HTV. The answer is no.

We have not encountered any manufacturer mentioning that you must pre-wash the material before using HTV or any outfit with a pre-washing instruction on the tag.

It is better to keep ensuring the HTV adheres properly to the material.

Keeping the material dry and smooth is important for using HTV on polyester. It is recommended to pre-heat your material instead (this will be discussed later in detail)

In a batch of polyester scarves, we noticed that the ones that were not pre-washed adhered better to HTV, maintaining their texture and color, as compared to the pre-washed ones that showed some peeling after application.

4. Have a Backup Plan

Let us say you have chosen a material you want to try out a new design. The first thing you should do is read the tag carefully.

Sometimes, it is mentioned whether you can use a heat press on that material because sometimes it can lead to discoloration (especially if it is too sensitive).

The discoloration can be temporary as well as permanent. Before using HTV on polyester, ensure you have read the tag correctly.

Also, the tag says that using a heat press can damage the material, but you still want to try and see how it works out.

Then, ensure you only risk something you can afford to lose or have a backup or duplicate for that material.

We tested the heat press on a similar but less valuable item when working on a custom polyester jacket.

We found that a slightly higher temperature was needed to avoid discoloration, which we wouldn’t have known without this precaution.

5. Increase the Timing

Did you know that the adhesive activation temperature in your heat transfer vinyl is much lower than in polyester?

If you want to ensure you do not damage the material while using HTV on polyester, press the material at a lower temperature but for a longer time.

As people often do, they sometimes press it for a shorter period and check if it has adhered properly, and if not, they press it again.

Although there is no harm, getting it right the first time is better. So when you put it in the washing machine for cleaning, it bonds well with the material.

We observed that pressing a polyester flag for a longer duration at a lower temperature prevented burning, while a shorter, hotter press caused the edges to curl.

6. Know the Material

We have discussed polyester being of different types and compositions, but what if the tag on the material is not entirely correct?

Often, the information provided on the tag is wrong, and what says itself to be 100% polyester could be something else, i.e., a mix of other materials, so what do you do in a condition like that?

Well, you must be extra cautious. Start testing it on a small fabric patch, or start with a lower temperature with a longer press time and slowly work up your temperature.

Just take precautions so that you do not end up burning your material.

A project involving ‘100% polyester’ curtains showed that the fabric was a blend, as revealed by a test patch. Adjusting the heat settings accordingly prevented damage.

7. Test Your Fabric

Since you might not know the accurate composition of your fabric, it is safer to test your fabric first.

Either on a small patch or a cut-out piece so that you don’t ruin the entire cloth.

Also, it is essential to check the effect of HTV on polyester and see how well it stays after putting it in a washing machine.

First, if your material is discolored when using the heat, press on it to see if the paint is peeling off when you put it inside the washing machine.

For instance, a test run on a small piece of a polyester blend dress saved us from ruining the entire garment as we adjusted the heat settings based on the test results.

8. Choosing the Right Kind of HTV

Choosing the right kind of heat transfer vinyl is essential, so you should avoid the cheap ones first.

You should find a long-lasting one with a strong adhesive and a different finish.

Switching between different brands for different designs is not recommended because that will only increase your costs.

Also, do you know the benefits of using one type of HTV? You do not have to work on the settings whenever you are already acquainted with using it, so it saves time and prevents mistakes.

In our experience, using a higher-quality HTV on a polyester sports jersey ensured the vinyl didn’t peel off after multiple washes, unlike a cheaper HTV we used on a similar fabric.

9. Check if Your Material is Heat Sensitive

Sometimes, specific polyester compositions, especially those marked waterproof ones, are heat-sensitive.

So, before you apply HTV on polyester, you need to check that out.

If you find out that it is marked “sensitive to heat,” you will have to use a different type of HTV that will release the adhesive at a lower temperature to get the HTV on polyester without ruining it.

For a heat-sensitive waterproof polyester jacket, we used a low-temperature HTV, which adhered well without damaging the fabric’s waterproof quality.

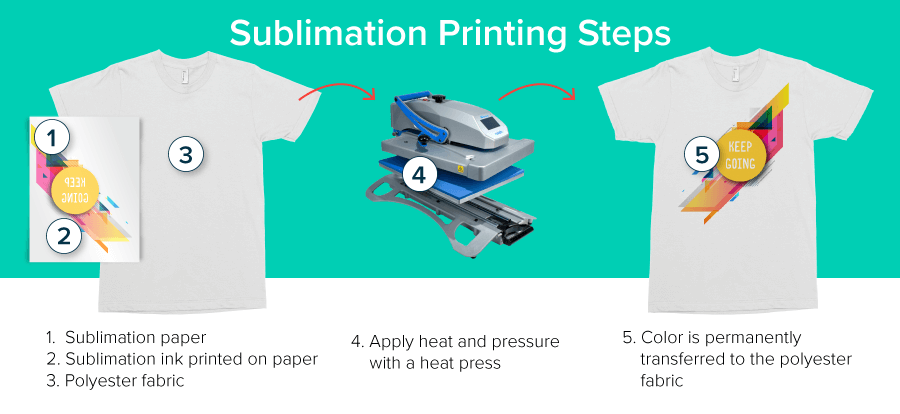

10. Using a Heat Press

Although using an iron is perfectly fine when you start with HTV and will work well as you progress and switch to more detailed designs, you might want to shift to a heat press.

It is the best way to control the settings and lets you decide how much heat you want on the material.

It helps provide a precise amount of pressure on your polyester material, which is extremely important for a perfect design finish.

For instance, switching to a heat press for a complex design on a polyester flag allowed for more even heat distribution and pressure, resulting in a more professional finish than an iron.

11. Don’t Let the Polyester Material Get Too Hot

This goes without saying, as we have already discussed the effect of HTV on polyester.

Start with a lower temperature; you can increase it slowly if you feel it must be increased.

You can fix or work out a solution if the HTV is not sticking properly on the material.

Still, if the material is destroyed due to overheating or the color is ruined, you cannot fix that.

So, starting safely and keeping the temperature under check is better.

Even in most heat presses, you will find that the temperature is not very high if you check correctly. It is mostly somewhere around 290 Fahrenheit.

While working on a delicate polyester blouse, we carefully monitored the temperature to prevent overheating, which had previously caused color fading on a similar fabric.

12. Make Sure That the Dyes Do not Bleed

Sometimes, when working with sublimated fabric, you must be very careful about applying the heat transfer vinyl because the pattern can leak from it into the vinyl.

If the vinyl keeps changing color, that can be a problem because, typically, HTV is not designed to block sublimation migration.

So, it would help if you were careful about picking up the right brand of HTV because some of them come with a sub-block feature to ensure that the outfit’s dye does not bleed.

For instance, when applying HTV on a sublimated polyester jersey, we selected an HTV with a sub-block feature, which prevented the vibrant dyes from bleeding into the vinyl.

13. Right Settings on Heat Press

This is a fundamental and significant thing, and if you are using a heat press, you must have noticed that it has a variety of settings on it.

If you are working with a polyester fabric, ensure you have the right setting.

Each will require a different setting for cotton or various versions of polyester compositions.

The temperature and pressure settings will differ even for different polyester compositions.

So, if you are working with a new composition, test it on a patch first.

Based on prior testing, adjusting the heat press settings specifically for a thin polyester fabric resulted in perfect adhesion without any damage.

14. Avoid Using Silicon Sheets

Sometimes, while using HTV on polyester, people prefer a heat press pillow or a silicon sheet.

Although they work best when you are working with outfits that are a little uneven with buttons and zippers.

So, if you use them on something plain, such as polyester, you might not want to use them because it will only make it difficult to guess the right pressure and temperature.

Using a thin Teflon sheet is best if you still want a sheet. They serve the same purpose and ensure your material does not stick to the vinyl.

In our experience, using a thin Teflon sheet instead of a silicone sheet while applying HTV to a polyester tablecloth resulted in a smoother application.

The thin sheet allowed for better temperature control and even pressure.

15. Pre-Heat Your Polyester Material

As we discussed earlier, it is recommended to pre-heat your material before using the HTV on polyester.

Pre-heating does not just open the pores of the fibers but also helps evaporate any slight trace of moisture that might be present on the piece of cloth.

Also, pre-heating ensures no wrinkles on the cloth, which is necessary before applying HTV on polyester.

As mentioned earlier, smooth and dry material is essential for good results.

By pre-heating polyester tote bags before applying HTV, we eliminated moisture and wrinkles, resulting in a smoother finish and better adherence to the vinyl.

Final Thoughts

These are some valuable tips you must remember while using HTV on polyester.

Remember, being a designer and printing HTV on t-shirts and other outfits is cool, but making it stay as good as new in the long run requires some hard work.

So, if you are working with a big batch or just learning, then knowing these tips, abiding by them, and being a little more vigilant will go a long way in giving you the perfect finish for your products.

We hope this article was helpful, and if you have any further doubts, you can always reach out to us in the comment section below.