It is strongly not recommended to use garage doors with a broken spring. This breakdown will lead to the failure of the automatic drive since the total weight of the gate is no longer compensated by the torsion assembly. Also, the operation will lead to the tangling of the cables, which will entail a longer and more expensive repair. In emergency cases, when there is no time to wait for the manufacture of the spring, it can be welded. This is a temporary and short-lived solution. And the duration of operation of such a spring depends solely on the properties and quality of the metal from which it is made. And most often, such a spring will burst again within two weeks but will allow you to make and install a new spring.

How to Choose a Spring for Replacement?

Typically, the need to replace the garage door springs arises quite a long time after the start of operation of the structure, when the desired plate is already overwritten, and the numbers become unreadable. In this case, torsion springs will have to be chosen differently. If you need to perform spring garage door repair, contact specialists at fixgaragedoors.ca.

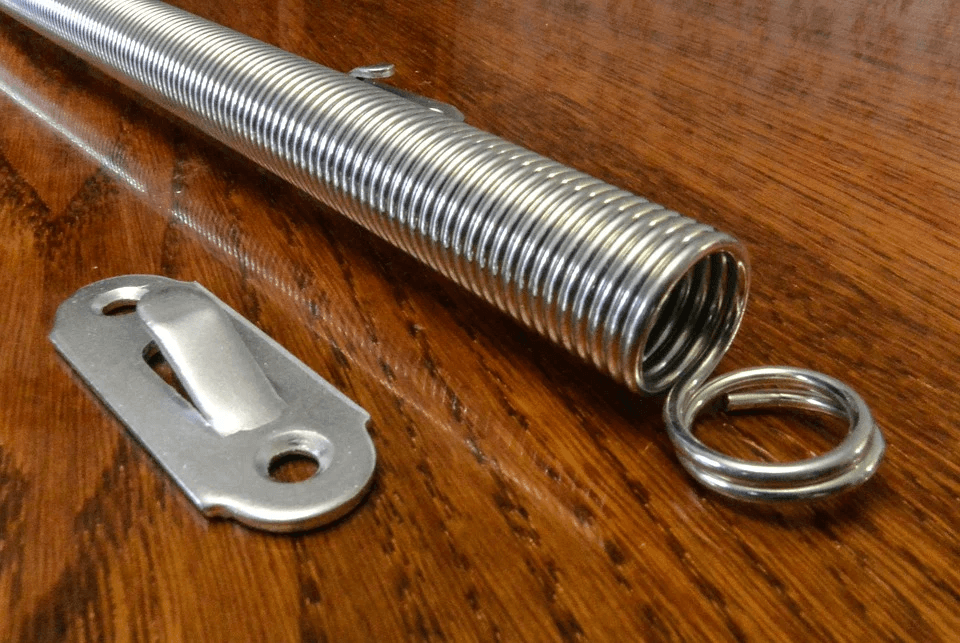

To select these details of sectional doors as accurately as possible, you will need to independently determine the following parameters:

- Assignment (left or right side). When determining the side, it is important to be inside the garage. To make it easier for users to choose, many reputable manufacturers make left-hand torsion springs with only a red stripe, while right-hand ones may have blue lines or other colour markings. This allows you not to confuse the springs.

- The total length of the product, including the cover.

- The outside diameter of the part.

- The cross-sectional diameter of the wire from which the torsion mechanism is made.

In some cases, manufacturers or dealer centre specialists are asked to clarify the dimensions of the garage opening, the type of lifting mechanism, and the presence or absence of a gate in the sectional leaf. At the time of order, it is critical to ensure that the torsion springs are supplied complete, including the cap and tip. This is a rather crucial point since self-removal of these elements and installation on a new spring takes a lot of time, while the slightest mistake in such a process can cause irreparable consequences in the future.

How to Install a Spring on Garage Doors?

After you have bought newly assembled parts, you can start replacing the sectional door springs:

- Release the mechanism.

- Remove the cable from the bottom bracket.

- Remove the inertial details of the gate (shaft, ratchet couplings, bearings, retaining rings and other parts).

- Place the shaft on the floor carefully especially if you have porcelain tile, remove the old spring from it and install a new part.

- Reassemble the inertial mechanisms and install them on the factory seat above the garage opening (either on a beam or rails, depending on the type of lifting mechanism of a particular gate).

- Attach the cable to the regular places in the lower brackets, and adjust the gaps of the inertial mechanism, which are located on the shaft.

Some Recommendations

We advise you to pay attention to the following aspects:

- Always replace all springs at once.

- If one of the springs on the gate breaks, all other details are at the limit of the calculated strength and can also break at any time.

- An error in the selection of a new detail will lead to incorrect operation of the equipment as a whole. An incorrectly made detail will cause difficulties in adjusting the gate, or make it impossible to adjust it at all (the gate will quickly go down and rise hard, or, when such a mechanism is tightened, it will be closed with great effort). To a greater extent, this affects the operation of industrial-type sectional doors, due to the large weight and high intensity of their use.

To prolong the service life of torsion springs, it is advisable to carry out regular maintenance of sectional doors or door curtain beads around the windows: monitor the absence of accumulated dust and dirt, and lubricate the cleaned parts twice a year (it is recommended to use silicone-based sprays that minimize protective coating abrasion and metal corrosion).